24 Feb Ultimate Guide to Excavator Undercarriage Maintenance: Extending Track Life

How to maintain the excavator undercarriage parts?

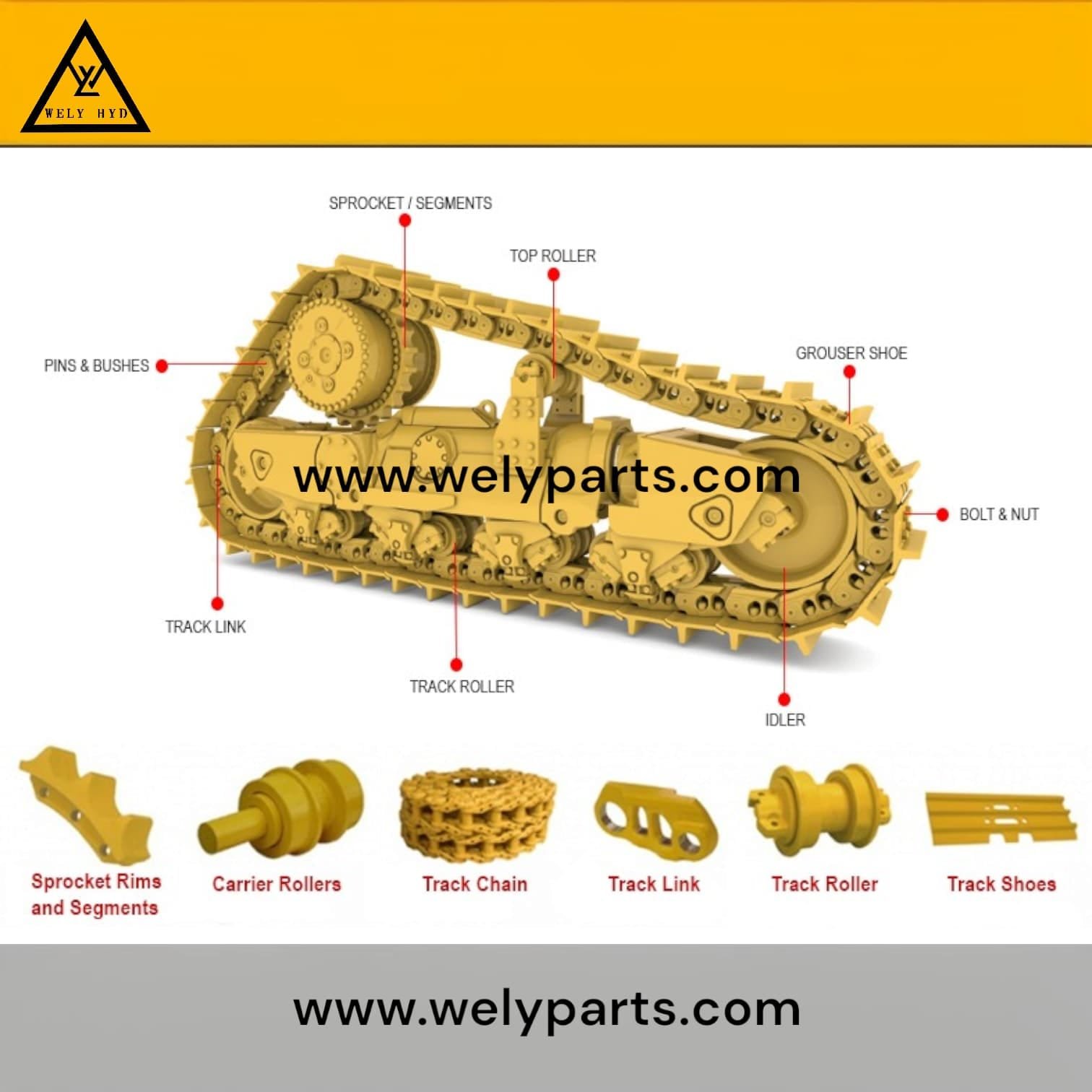

Your excavator’s undercarriage (often called the “four-wheel area” or “tracks”) is crucial for performance. It’s the part that takes the most abuse, directly impacting digging power, travel speed, and overall efficiency. Neglecting undercarriage maintenance leads to premature wear, costly repairs, and significant downtime. This guide provides essential tips for maintaining your excavator’s undercarriage, extending its lifespan, and maximizing your investment.

1. Track Rollers (Bottom Rollers):

Problem: Track rollers are constantly exposed to harsh conditions. Prolonged immersion in mud and water accelerates wear and corrosion. In winter, trapped water can freeze, damaging seals and causing oil leaks. Damaged rollers lead to issues like track misalignment, reduced travel speed, and increased stress on other components.

Maintenance:

- Daily: After each workday, raise one side of the excavator and rotate the tracks to dislodge mud, rocks, and debris.

- Winter: Ensure rollers are dry before freezing temperatures. Frozen water damages seals, leading to oil leaks.

- Inspection: Regularly check for oil leaks, cracks, and excessive wear. Replace damaged rollers promptly.

2. Carrier Rollers (Top Rollers):

Problem: Carrier rollers support the top run of the track. Damage prevents the track from running straight, increasing wear on other undercarriage components. These are typically sealed units and cannot be easily repaired; replacement is usually required.

Maintenance:

- Inspection: Regularly inspect for damage, wobbling, and unusual noise.

- Cleaning: Remove accumulated debris to prevent restricted rotation.

3. Idlers (Front Idlers):

Problem: Idlers guide the track and absorb shocks. Proper tension, maintained by the recoil spring, is crucial. Improper tension or a damaged recoil spring leads to excessive wear on the tracks and other components.

Maintenance:

- Tension: Regularly check and adjust track tension according to the manufacturer’s specifications. Too tight causes excessive wear, too loose can cause track derailment.

- Inspection: Inspect the idler face for wear and the recoil spring for damage.

4.Sprockets (Drive Sprockets):

Problem: Sprockets drive the tracks. Operating with the sprockets leading (instead of trailing) causes excessive wear on the sprocket teeth and track links, and can even damage the X-frame. Debris buildup inside the travel motor guard can damage hydraulic lines.

Maintenance:

- Operating Practices: Always operate with the sprockets trailing.

- Cleaning: Regularly remove the travel motor guard and clean out accumulated dirt and debris to prevent damage to hydraulic lines.

- Inspection: Check sprocket teeth for wear and replace when necessary.

5. Tracks (Track Chains/Track Shoes):

Problem: Tracks experience the most direct wear. Track shoes (the ground-contacting plates) come in different styles (standard and extended) for various ground conditions. Debris trapped between shoes can cause bending and cracking. Incorrect track tension accelerates wear on all undercarriage components.

Maintenance:

- Track Shoe Selection: Use appropriate track shoes for the job (standard for general earthmoving, extended for soft or muddy conditions).

- Cleaning: Regularly remove debris trapped between track shoes.

- Tension: Maintain proper track tension

- Inspection: Check for bent or cracked shoes and worn links.

Conclusion :

Proper undercarriage maintenance is essential for maximizing your excavator’s performance, minimizing downtime, and reducing operating costs. By following these guidelines, you can significantly extend the life of your undercarriage and ensure your machine operates efficiently. Regular inspections, proper cleaning, correct track tension, and timely component replacement are key to a healthy and productive excavator.

Sorry, the comment form is closed at this time.